About subpage - concrete

Polymer-Based Internal Curing Agents

As concrete cures, it tends to shrink and crack unless protective measures are taken. These cracks shorten service life and increase maintenance costs, especially in flat-work such as pavements, parking garages, tilt-up panels, and warehouse floors. Shrinkage is also a concern for low-water high-performance concrete used in skyscrapers and dams, as well as for high–surface area structures produced by 3D printing.

Traditionally, contractors limit shrinkage with external methods—such as wet burlap coverings or spray-on coatings—or with internal curing using water-filled lightweight aggregate (LWA). However, these approaches are labor-intensive, slow construction schedules, and, in the case of LWA, can significantly increase project costs and be difficult to source across the U.S.

Superabsorbent polymer (SAP) particles offer an alternative internal curing strategy. Added at small doses (typically less than 0.5% of cement weight), dry SAP particles rapidly absorb mixing water and swell. This temporarily reduces free water, promoting early formation of a dense cement microstructure. As curing progresses and humidity drops, the SAPs gradually release their stored water, sustaining hydration and reducing self-desiccation, shrinkage, and cracking. Click here to watch Prof. Erk’s lecture at University of Louisville’s ERINC Soft Matter Initiative.

Internal snapshots of SAP-cured cement, from the swelling of dry SAP within the first few minutes to the release of fluid as the cement cures. (Bose and Erk, 2018)

Field Trials with Commercially Available SAP Particles

For any new internal curing technology to be adopted, it must be easy for ready-mixed concrete producers and contractors to batch and place. To evaluate this, our group partnered with Shelby Materials to conduct a full-scale field trial using commercial SAP particles donated by SNF Floerger, with support from the Joint Transportation Research Program and the Indiana Department of Transportation (INDOT).

The SAPs were packaged in 1-lb dissolvable bags, each providing the proper dosage for 1 cubic yard of INDOT Class C concrete. Slabs produced with SAPs showed higher compressive and flexural strength than SAP-free controls and were 30–50% stronger than slabs cured only with a surface-applied curing compound. Mixtures containing SAPs and slag achieved some of the largest strength gains and exhibited very low permeabilities (TRR 2025). Click here to watch a recent webinar hosted by the Slag Cement Association on our work. Our public report is coming soon.

Bagged SAP was used for slabs in 2023 field trials with INDOT (left). In these trials, slabs were both internally cured with SAP and externally cured with a surface-applied curing compound (right). (Erk 2023)

Laboratory Experiments with Custom-Synthesized Hydrogels

Beyond commercial SAPs, Prof. Erk’s group is developing new hydrogel compositions designed to actively influence cement hydration by controlling the nucleation and growth of hydrated phases. Over the past decade, our group has shown that a hydrogel’s polymer network chemistry and structure directly govern its internal curing behavior in cementitious systems, as summarized in this 2022 review article. Key discoveries include:

Multivalent ions in cement pore solution strongly affect swelling and water transport. Some hydrogel formulations experience reduced swelling, rapid desorption, or the formation of a stiff outer shell. Materials & Structures 2015, Materials & Structures 2016, Gels 2017

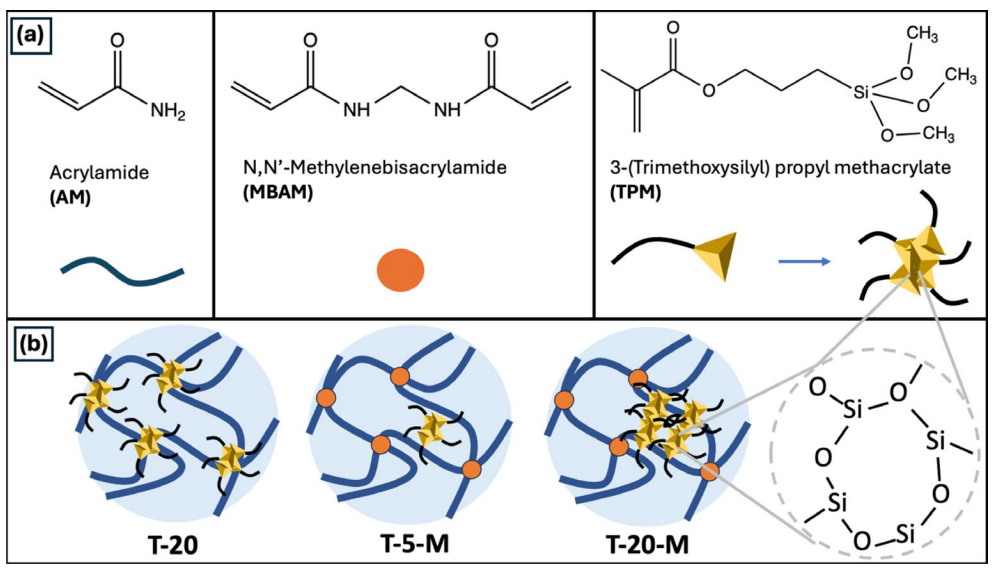

Specific polymer chemistries promote high-strength hydration products. Acrylamide-rich hydrogels and silica-composite particles can encourage the formation of dense, high-strength inorganic phases within the microstructure. Advances in Civil Engineering Materials 2018, SAP 2019, CCR 2021, Erk Patent 10,752,547

Hydrogel-based internal curing can maintain or improve strength across a wide range of water-to-cement ratios, supporting its use in diverse mixture designs. CBM 2022, JTRP 2022, Materials & Structures 2024

These findings highlight how the chemical sensitivity of cement to hydrogel properties can be leveraged to create multifunctional admixtures. Our current research efforts focus on hydrogels with controlled gradients in polymer chemistry and structure to direct C–S–H nucleation and morphology, an approach aimed at high-strength, printable mortars. Recent work incorporates organic silane molecules into the polymer network to tailor hydrate development (Erk Provisional Patent 19/060,199), and the group is also exploring low-cost SAPs produced from upcycled absorbent materials from diaper manufacturing in collaboration with P&G (Erk Provisional Patent 19/076,719).

CryoSEM was used to track the nucleation and growth of cement hydrates in the vicinity of novel silane-functionalized hydrogel particles in cement paste (Seshadri, et al., Polymer 2025).

Chemical structures and schematics of silane-functionalized hydrogels that were incorporated into a 3D printable mortar (Hiller, et al., Journal of Applied Polymer Science 2026).